Main Features

- Touch screen + PLC to control tool gap and working process.

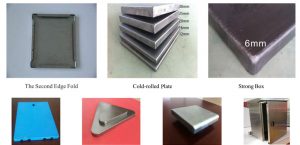

- Each corner can be identify different inner radius according to thickness.

- Forming the R angle does not require open angle welding. It only needs to pre-bend the two sides of the R angle by 90 degrees on the bending machine, and then roll and form the whole machine on this machine to automatically cut the excess edge material.

- The die types are divided into bending lower die, forming roller upper die and forming lower die. The bending die is the same as the ordinary bending die, depending on the thickness of the plate. The upper die of the forming roller depends on the R angle that needs to be formed. The forming lower die is determined by the R angle of the upper die of the roller minus the thickness of the plate. A lower die has four different R angles.

- The forming R angle is the same but the plate thickness is different. It is not necessary to replace the forming roller upper die and forming lower die, only to adjust the gap between the forming roller upper die and the forming lower die.

Parameter

|

Model

|

CF-3050

|

|||

|

Total Power

|

5.5KW

|

|||

|

Voltage

|

3Phase 4Wire 220V/380V

|

|||

|

Oil Pump Power

|

3.7KW 380V

|

|||

|

Air Pressure

|

≥0.8Mpa

|

|||

|

Processing Capacity

|

Material

|

Plate Thickness

|

Flange Height

|

Corner Radius

|

|

Cold Rolled Steel Plate

|

0.6mm

|

≤9mm

|

1.5-50

|

|

|

0.8mm

|

≤12mm

|

|||

|

1.0mm

|

≤15mm

|

|||

|

1.2mm

|

≤18mm

|

|||

|

1.5mm

|

≤22mm

|

|||

|

2.0mm

|

≤26mm

|

|||

|

3.0mm

|

≤30mm

|

|||

|

Stainless Steel

|

0.8mm

|

≤14mm

|

||

|

1.0mm

|

≤18mm

|

|||

|

1.5mm

|

≤20mm

|

|||

|

2.0mm

|

≤24mm

|

|||

|

Aluminum Plate

|

0.8mm

|

≤12mm

|

||

|

1.0mm

|

≤15mm

|

|||

|

1.5mm

|

≤20mm

|

|||

|

2.0mm

|

≤24mm

|

|||

|

2.5mm

|

≤28mm

|

|||

|

3.0mm

|

≤30mm

|

|||

|

Workpiece Size

|

Minimum 170*170mm Maximum 6000*6000mm

|

|||

|

Weight

|

2300kg

|

|||