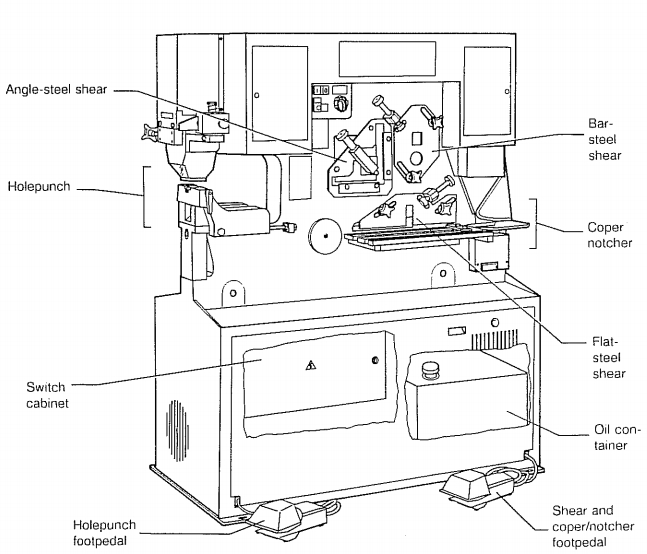

1,Punching Station

The large punch bed area has a removable front block and is designed to give a very wide range of punching applications. A punch table with rules and guides for repetition work are fitted as standard machine.

2,Section cutting station

The machines are fitted as standard with blades for cutting round and square bars. With extra device, the machines are able to cut, in this aperture, channel, joist, T-section and many other special profiles.

3,Angle station

This station provides large capacity angle cutting at 90° and 45°. Angles between 45° and 90° can be achieved by first cutting at 90° and then flange trimming to the required angle in the shearing station.

4,Shearing Station

The shearing unit is fitted with a simple robust holddown which is adjustable to any thickness of material within the cutting capacity of the machine. The shear feed table with adjustable guides is fitted to allow accurate feeding of materials. The guide can be adjusted to allow mitre cutting up to 45° for flat bars or to trim the flangles of angle.

5,Notching Station

The notching station is fitted as standard with a rectangular notch table with adjustable back stops, allowing repetitive positioning.

Two shielded foot controls

For two operator utilisation, the hydraulic system is activated by two shielded foot controls,one operating the punch end cylinder, the other operating the shear end cylinder. The shear cylinder provides the power to the three shearing and the notch stations.

Low maintenance

The system gives accurate power inching at all five work stations and allows the machine to be stopped at any position giving safe and accurate tool setting and work positioning. Limit switches at both ends of the machine control stroke length at all stations. Centralised lubrication is metered by one-shot system, being only one feature of the low maintenance requirement.

| Model | MULTI 60 | MULTI 70 | MULTI 80 | MULTI 95 | MULTI 125 | MULTI 175 |

| RATED CAPACITY | 60T | 70T | 80T | 95T | 125T | 175T |

| PUNCHING | ||||||

| Hole Punching(D x T) | 28×15 | 26X20 | 28X20 | 27X25 | 32X25 | 40X32 |

| Max. hole punching(D x T) | 57×8 | 57X9 | 57X10 | 57X12 | 57X16 | 57X22 |

| Stroke | 55 | 55 | 55 | 80 | 80 | 80 |

| Standard depth of throat | 305 | 305 | 305 | 355 | 355 | 625 |

| Extend depth of throat | 625 | 625 | 625 | 625 | 625 | 625 |

| Max. hole size | 57 | 57 | 57 | 57 | 57 | 57 |

| Max. hole size | 160 | 160 | 160 | 160 | 225 | 225 |

| Max. section steel | 305 | 305 | 305 | 305 | 305 | 380 |

| SHEARING | ||||||

| Max. thickness for plate | 230X20 | 300X20 | 300X20 | 380X20 | 380X25 | 380X30 |

| Max. width for plate | 375X10 | 375X15 | 450X15 | 480X15 | 600X15 | 600X20 |

| Cut corner in angle steel, Max. 45 degree | 100X15 | 100X15 | 100X15 | 120X15 | 120X15 | 125X15 |

| ANGLE CUTTING | ||||||

| 90° | 130X13 | 130X13 | 150X13 | 150X15 | 150X18 | 200X20 |

| 45° | 70X10 | 70X10 | 70X10 | 80X10 | 80X10 | 80X10 |

| SECTION CUTTING | ||||||

| Round steel/Square steel | 45 | 45 | 45 | 50 | 55 | 65/55 |

| Channel steel/H steel | 130X65 | 130X65 | 130X65 | 160X90 | 200X100 | 200X100 |

| T steel* | 90X12 | 90X12 | 90X12 | 100X12 | 120X12 | 150X15 |

| NOTCHING | ||||||

| Plate thickness | 10 | 10 | 12 | 12 | 12 | 16 |

| Width-rectangle | 45 | 45 | 40 | 52 | 60 | 60 |

| Depth-rectangle | 90 | 90 | 90 | 100 | 100 | 100 |

| Depth-V shape | 60 | 60 | 60 | 70 | 80 | 80 |

| Cut edge | 100X10 | 100X10 | 100X10 | 100X13 | 100X13 | 100X14 |

| CONER NOTCH | ||||||

| Max. corner cutting ability | 250X6 | 250X6 | 250X6 | 250X6 | 250X6 | 250X6 |

| TUBE NOTCH | ||||||

| Max. outside diameter for tube | 83 | 83 | 83 | 108 | 108 | 165 |

| BENDING | ||||||

| flat steel bending | 250X12 | 250X13 | 250X13 | 250X20 | 250X22 | 250X25 |

| plate bending | 500X3 | 500X3 | 500X3 | 500X3 | 700X3 | 700X4 |

| PUNCHING AT NOTCH STATION | ||||||

| Depth | 125 | 125 | 125 | 125 | 125 | 125 |

| Max. ability | 38X7 | 38X8 | 38X8 | 38X10 | 38X12 | 38X13 |

| TECHNICAL DATA | ||||||

| Power for main motor | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 |

| Net weight for machine | 1570 | 1620 | 1925 | 2730 | 3100 | 5550 |

| Machine size (L x W x H cm) | 164X71X178 | 164X71X180 | 190X79X191 | 190X79X191 | 200X80X203 | 270X112X216 |