Product details

Proper tooling maintenance is critical to produce high quality parts, increase machine uptime and extend tool life. RSM Grinding Machine ensures the proper result for every sharpening operation. With RSM’s easy-to-use touch screen interface, powerful high-output motor and ability to accept any tooling style, keeping your tooling in optimal condition has never been easier.

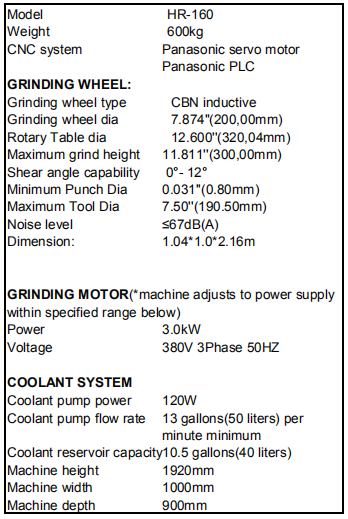

TECHNICAL SPECIFICATIONS

Features of RSM Grinding Machine

1.Touch-screen interface simplifies all set-up and maintenance operations.Supports multiple language and units of measure.Easily updateable software via USB port and SD card.

2.Data tracking-Number of punch press tools sharpened, wheel and coolant life, motor life and more. Predictive wheel replacement warning.

3.Solid-surface 7.8”(200mm)CBN grinding wheel optimizes performance. Eliminating the perpendicular solts directly translates to a longer-lasting wheel.

4.Innovative design allows automatic coolant flow directly through the grinding wheel.

5.On screen alerts/warnings for “Add Coolant”(low coolant) and “change filter”(high coolant).

Easy operation:

1.Ideal for unsupervised operation, just press”Start grinding” and the machine will sharpen the tool without assistance.

2.Light signals when current sharpening cycle is finished no need to wait by machine.

3.Store multiple programs to ensure consistency no matter who operates the machine.

4.Powerful 3.0kw motor can handle the largest tools.

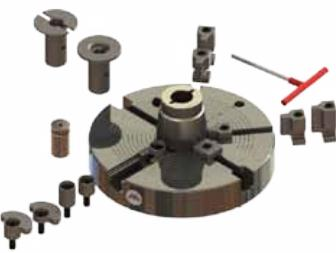

Flexibility

1.Three standard programs(one each for small, medium and large tools)and two user-customizable programs. Full manual mode for unique situations also included.

2.Universal fixture accommodates virtually all tooling styles.

3.Fine grind depth and removal rate settings provide maximum flexibility, reliability and consistency.

4.Angular table adjustment from 0°to 12°allows shears(including whisper and rooftop)to be ground on punches for optimal punching efficiency.

Convenience

1.Status report screen with complete sharpening and wheel maintenance datalog.

2.Two drawers for convenient storage of tooling awaiting maintenance or other items such asmeasuring instruments.

3.10.5 gallon(40 liter)coolant tank on wheels. Easy-to remove for changing coolant and tank cleaning.

4.Hand sprayer

Safety

1.Fully enclosed work area ensures safety.

2.The operation door was interlock with fully and firmly enclosed.

3.Abrasive mist contained during sharpening process. Keeps work area clean while eliminating slip hazards. Keeps abrasive sharpening mist out of the air and off of other expensive machinery.

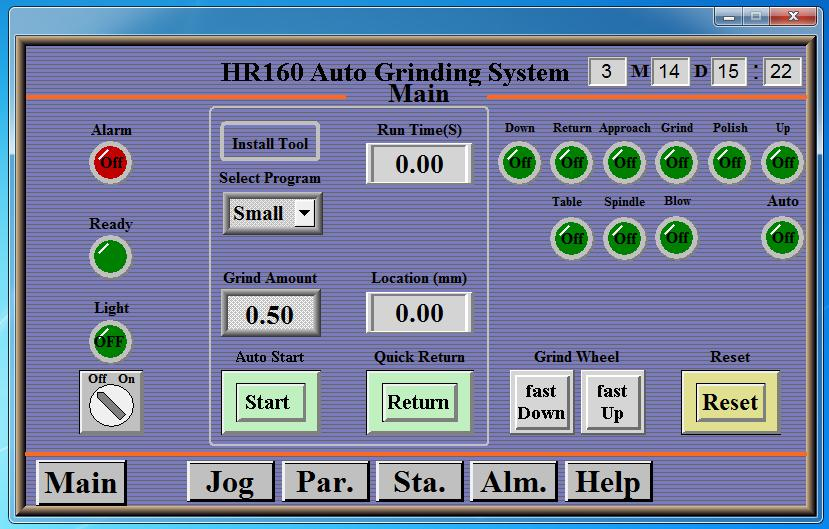

TOUCH SCREEN CONTROL PANEL

MAKES OPERATION EASY!

STEP 1- STALL Install tool into universal grinding fixture.

STEP 2-ENTER Enter the amount you want to remove

STEP 3-SELECT Select from one of three pre-set programs, or create two custom programs.

STEP 4-START Press “Start Grinding”for automatic operation!

RSM Grinding Machine accommodateds a full range of punch press tool styles:

Thick Turret;

Thin Turret;

Trumpf Style;

Murata Wiedemann;

Multi Tools

1.A wide variety of punch press tooling systems are fully compatible with RSM Grinding Machine.

2.Small diameter punches can be ground without breakage.

3.Rooftop shear may be sharpened easily by using the graduated tilt mechanism.

4.RSM even sharpens complicated whisper shears on Trumpf-sytle punches.

5.Large station dies can be hsarpened quickly with high quality surface finish