Functions:

The CNC stud welding machine is the latest CNC equipment that integrated automatic stud feeding and welding,developed based on traditional manual stud welding machine, integrated with independent R&D automatic stud feeding mechanism、automatic welding head、automatic control system and etc. The machine can equip with multiple welding heads and weld multi-specification studs which can replace manual welder, positioning accuracy, welding firmly, wide application materials:cold plate、stainless steel、aluminium、galvanized plates and etc.

CNC stud welding machine can weld multi-specification studs on the metal surface quickly and stably, without sunk, bulge on the backside of plate, and no need the traditional processes of drilling、riveting、 arc welding and post treatment; which can realize the complicated welding requirements by CNC programming.

Stud welding Technology greatly increase the production efficiency, reduces the production costs and improves the quality.

Application industry: electric, electronic, boiler, electric power construction, decoration and appliances, elevator , automobile industry, shipping industry, space industry and etc.

Specification:

The machine is consists of frame unit、clamping device、automatic welding head、electric driving system、welder、automatic stud feeding unit,details are as below:

- Frame Structure

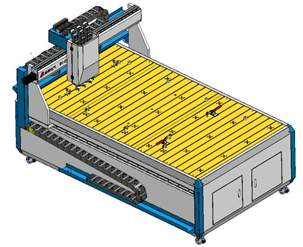

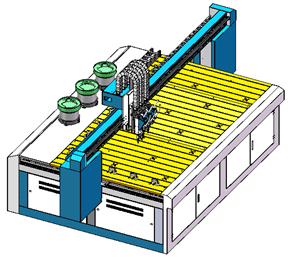

There are “Vertical Structure” and “Horizontal Structure” two different structures, global design is based on structure of advanced foreign experience、combined with our rich design experience.

The machine is steel frame+Aluminium gantry structure, ensure the frame strength and running precision, efficiency and durable.

“Vertical structure” means that long-side direction is running direction of gantry, which mainly process less than length 2200mm work piece, lead screw+guide rail motion way. “Horizontal structure” means that short-side direction is running direction of gantry, which mainly process more than length 2200mm, less than width 1200mm work piece, high-precision synchronous belt motion way.

- Clamping Device

Moveable type or fixed type can be chose upon requests. Moveable type can clamp workpieces with ease, angle adjustable; fixed type can clamp different height products, height adjustable.

- Automatic Welding Gun

3 welding guns, two different kinds of welding heads: vertical and oblique. It is recommend to use oblique welding gun, the advantages are that there are stud clamping and conductivity mechanism inside the welding head,so that life time and firmness degree improved greatly.

e.g. At same voltage value, compared with vertical welding head, oblique welding head has obvious advantages on galvanized materials.

- Welding Head Driving Unit

The height of Z axis welding head is adjusted by servo motor or cylinder; motor height is 300mm, cylinder is 150mm, For different workpieces,150mm under the common condition ,300mm in case of programming. The design ensure large working area, pressure adjustable, easy operation.

- Automatic Stud Feeding Device

Automatic Stud Feeding Device is consist of vibrating stud picker+Pneumatic stud feeder+ stud detection. Open structure is easy to maintain.

- Control System

Electric driving system is all-in-one CNC +servo motor system, imported dedicated multi-axis linkage controller system which developed based on industry robot system, stable and reliable, powerful, movable human-interface color hand-held box easy to operate、program、positioning.

Three-axis-in-one servo motor control system, small in size, easy installation, simple connection, stable running. We can offer teaching/CAD/coordinate position programming way to different products、different quantity, different management.

With infrared ray indicator, hand wheel locating, import dedicated software into computer by CAD drawing and then put into system by U disk. Input Welding coordinate to system form by drawing or processing file, and then being processing program file for production. According to our factory use habits, master basically choose teaching way because that operation requirements for operators culture is not high, the production site can switch different kinds and quantity products at any time, don’t need to look for the drawings, documents, according to the number of charged or laser finished workpiece directly teaching programming, both fast speed and low error rate.

- Welder

Independently developed double capacity welder with digital

communication function, there are two groups of capacitance, one work, one storage, production efficiency doubled, long time doubled, charging time next to nothing.

Communicate with control system, the welder can adjust the charging voltage value every time according to the requirements for different studs from control system, one welder can weld different studs at the same time which is different from other brands that need to adjust parameters after welding one kinds of stud.