1. Frame construction. Machine frame with Q235 steel, and working table with 60mm Q345thickness low alloy steel.Machine overall rigid, durable.

2. The machine body is tempered with natural gas to eliminate welding stress and reduce equipment deformation. Through sandblasting treatment to ensure the painting effect of the paint surface.

3. The machine adopts precision copper gear and helical rack drive, Taiwan Hiwin roller heavy-duty linear guide, the moving speed can be adjusted by frequency conversion, and the working process is stable and efficient.

4. The main motor adopts 5.5KW main shaft servo and planetary reducer synchronous belt transmission, which greatly increases the stability of the machine’s operation, and improves the machine’s running speed and grooving power.

5. The tool holder transfer device of the slotting machine uses SFSR silent ball screw and QH silent guide rail to ensure high accuracy.

6. The machined parts for slotting are fixed by hydraulic clamping system, the slotting speed is fast and strong clamping is ensured. The hydraulic system is equipped with accumulator compensation and overflow valve, the motor works in gaps, which saves energy and the hydraulic system is safe.

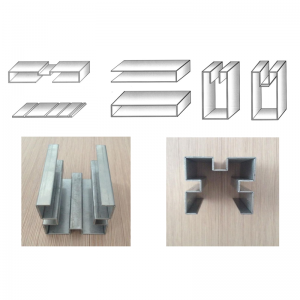

7. The machine uses four knives to process the “V” groove, so the cutting amount is evenly distributed and the deformation of the processed part is reduced. And the optional micro cooling system can prolong the service life of the tool and reduce the production cost.

8. The machine can be processed longitudinally and transversely, and has a process to realize the “front and back” processing function of the plate.

9. Just enter the keyboard and processing program to start using. According to the different materials, the processing speed can be adjusted by the knob, which is convenient for the operator to operate.

10.Through the screen, you can understand the process in processing. The sensor is used to ensure the safety of the operator.

11.When the equipment is abnormal, an alarm message appears on the display, easy to repair.

12.When the machine is processed, labor is only required for the placement and removal of the processed parts, so labor can be saved.

13. The table of the machine has a self-repairing function. During process, the customer can plan the table top according to their own requirements to ensure the machining accuracy.

14.Water cooling system, cooling blades, reduced wear, increase using life.