Main Features

- 40ton, 60ton, 100ton…

- Y1/Y2 axis adopts grating scale or magnetic grating scale feedback full-closed loop control mode, precise positioning control, repeat positioning accuracy of ±5μm

- Intelligent safety light curtain monitoring ensures operator safety

- Smart tool load monitoring ensures tool safety

- Five-wire touch screen, high reliability with a service life of more than 10 million times, and the operation process is simple and fast.

- Bending pressure automatic calculation function, alarm prompt when the pressure exceeds the limit range

- “Direct” calculation of back gauge position

- Angle intelligent compensation function: According to sheet metal material characteristics, die size, material thickness, bending angle and other sheet metal process parameters, combined with the angle calculation model of the CNC system, any sheet metal only needs one trial break

- Arc continuous bending function

- Die parameter library: establish a mold parameter library for customers, which is convenient for customers to quickly call parameters for sheet metal bending

- Password protection function

- All-electric servo CNC bending machine, power saving and green environmental protection

Specification

| Model | IS-4016 | IS-6025 | IS-10032 |

| Bending Force | 400KN | 600KN | 1000KN |

| Bending Length | 1600mm | 2500mm | 3200mm |

| Motor Spacing | 1250mm | 2000mm | 2800mm |

| Throat Depth | 410mm | ||

| Opening Height | 470mm | ||

| Slider Tilt | ±30mm | ||

| Speed | |||

| Y Axis Fast Approach Speed | 220mm/s | 200mm/s | 180mm/s |

| Y Axis Bending Speed | 50mm/s | ||

| Y Axis Return Speed | 220mm/s | 200mm/s | 180mm/s |

| X Axis Fast Approach Speed | 500mm/s | ||

| R Axis Fast Approach Speed | 200mm/s | ||

| Z1/Z2 Axis Fast Approach Speed | 400mm/s | ||

| Repeat Positioning Accuracy | |||

| Y Axis | ±0.01mm | ||

| X Axis | ±0.02mm | ||

| R Axis | ±0.1mm | ||

| Z1/Z2 Axis | ±0.1mm | ||

| Stroke | |||

| Y Axis | 200mm | ||

| X Axis | 500mm | 600mm | 600mm |

| R Axis | 200mm | ||

| Z1/Z2 Axis | 800mm | 1800mm | 2500mm |

| Size | 2400*1388*2439mm | 2900*1388*2439mm | 3600*1722*2664mm |

| Weight | 3500kg | 5300kg | 7800kg |

configuration

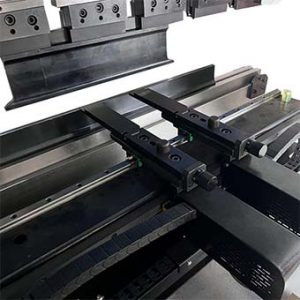

Back gauge system

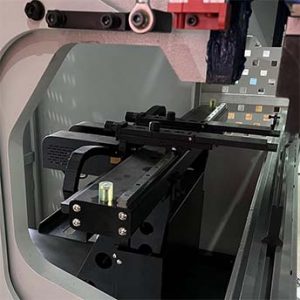

control system

The CNC system is a suspended operating station that can swing freely in the operating area, and the pedal-operated operating system can operate. It enable operator to do off-line programming.

Safety Device (Optional)