Why Tandem CNC Press Brake?

- Tandem CNC Press Brake is combined from two sets of press brake tandem achieving synchronized working single machine, where the two machines can also be used separately to improve production efficiency.

- The tandem press brake can process long workpieces, especially suitable for the processing and manufacturing of long workpieces such as the road lamp pole and power pole of the urban construction and expressway.

Specification

| Model | 2EHP-40050 | 2EHP-120090 | |

| Bending Force(kN) | 2-4000 | 2-12000 | |

| Bending Length(mm) | 2-5000 | 2-9000 | |

| Distance Between Uprights(mm) | 4000 | 8000 | |

| Opening Height – Workbench not included (mm) | 600 | 1000 | |

| Throat Depth(mm) | 450 | 1000 | |

| Cylinder Stroke(mm) | 300 | 600 | |

| Oil Volume (L) | 2-2×120 | 2-2×420 | |

| Main Servo Motor Power(kw) | 2-2X7.9 | 2-2×25.2 | |

| Max Speed (mm/s) | Approaching speed | 100 | 60 |

| Working speed | 0-8 | 0-6 | |

| Returning speed | 100 | 60 | |

| Dimensions (mm) | Length | 2-5260 | 2-9350 |

| Width | 2350 | 4250 | |

| Height | 4700 | 7600 | |

| Weight(kg) | 2-34700 | 2-163000 | |

Machine Configuration

2EHP-40050 (400ton/5000mm) , 4+1 Axis / 2EHP-120090 (1200ton/9000mm) , 3+1 Axis

Standard Switzerland CYBELEC CT12 CNC Control System

Dual-Servo oil-electric Hybrid Hydraulic System

Servo motors and drivers dedicated to hybrid systems with high speed, high torque, high precision and low noise.

Mechanical Compensation Workbench

The CNC system controls the mechanical compensation table to ensure high-quality bending accuracy.

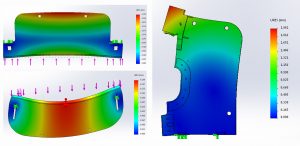

High Rigidity Frame

Frame: frame structure, composed of workbench vertical board, left and right side boards, connecting beams, mechanical compensation device, etc. The steel plate is integrally welded, and the internal stress is eliminated by high temperature annealing and other processes.

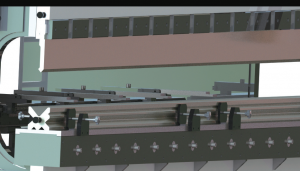

Bending Toll & Fast Clamping

The die consists of two parts, the punch die and the lower die, which are integrally quenched and durable. The punch die is installed on the upper beam and fixed by the heavy-duty clamping device. The lower die adopts the form of a square die, which is convenient and quick to change.

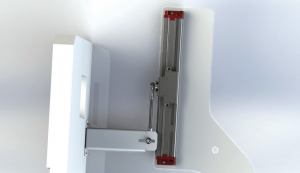

Front Support System (Standard)

According to the length of the workpiece, the supporting bracket can be manually moved to the appropriate position for fastening, and the supporting bracket can be adjusted in the horizontal and vertical directions.

High Precision Grating Ruler

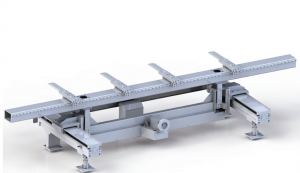

Back Gauge System

Servo-motor driven ball screw, has characteristic of high speed and high setting accuracy. Design of multi stage stops, to increase the positioning range, above the price invalue. Building block design, number of control axIs are available from single-axis X to multi-axis.

HMI Operation Interface

-

Our Factory