Main Features

- Mini CNC press brake, 12 ton 120KN

- Dual servo motor Drive-Technology provides high precision bending results.

- EP series bending machine does not need hydraulic oil, and is driven by electric cylinder, so as to avoid problems such as hydraulic pollution and oil temperature affecting the accuracy of the machine tool.

- Patented electric steel structure technology, using heavy-duty high-precision ball screw, high precision and long life.

- The electric cylinder is driven by the servo motor during bending, and the power consumption of the servo motor is very small during the fast down and return strokes, so this equipment is very energy-saving, compared with the same series of hydraulic bending machines, it can save energy by more than 50%.

- High precision DELEM CNC system

- 100% Pure electric power, with no oil.

- Up to 50% less energy consumption compared to ahydraulic press brake.

- Up to 35% faster compared to a hydraulic press brake.

- High efficiency and precision.

- High bending speed and less noise.

- Full bending length between side frames.

- Less maintenance cost.

- Eco friendly.

- Friendly user interface.

Specification

| Model | EP-1206 |

| Bending Force | 12Ton(120KN) |

| Bending Length | 600mm |

| Axis | 4 |

| Distance Between Column | 450mm |

| Throat Depth | 200mm |

| Stroke | 120mm |

| Opening Height | 420mm |

| Back Gauge Stroke | 200mm |

| Main Motro Power | 2*2.9KW |

| Motor | SANYO |

| CNC System | DELEM |

| Approach Speed | 200mm/s |

| Return Speed | 200mm/s |

| Bending Speed | 30mm/s |

| Repeat Positioning Accuracy | ±0.01mm |

| Size | 750*750*2020mm |

| Weight | 1350kg |

Configuration

-

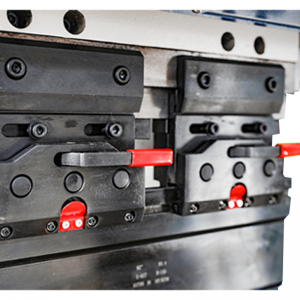

Top Tool Clamping

- MSD Safety Device

-

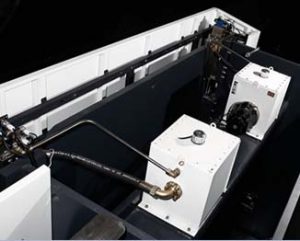

Backgauge

Application

- Suitable for BUSBAR, kitchen utensils, electric cabinets, new energy, energy storage, hardware, etc.