Now with Tool Insert! The new generation of joining technology, already proven in many ways!

The RSM-Joining-Systems:

The RSM-Joining-Systems:

Blending innovation with reliability, R-SIMITCH PRESSOTECHNIK engineers sheet metal joining systems for industry partners around the world. Sheet metal clinching is a cold-forming technique that joins two or more metal pieces without the use of fasteners, bolts, rivets or spot welding. Trusted by the manufacturing, automotive, appliance, housing, HVAC and furniture industries, R-SIMITCH sheet metal joining systems are an economical solution for your clinch joining system needs.

Used for high-strength fastening, sheet metal clinching produces a button-type joint that does not impact the surface finish. Additional advantages of R-SIMITCH systems include:

*Reliability: RSM guarantees the joint strength values provided by our clinching systems.

*Versatility: R-SMITCH clinching systems are commonly used for sheet metal, but can be used for other material types as well.

*Eco-Friendly: RSM sheet metal clinching creates no wasted material, and is a clean, quiet process.

*Budget Friendly: This type of sheet metal joining is more affordable than spot welding and other fastener techniques.

The RSM-Joining-Systems:

Blending innovation with reliability, R-SIMITCH PRESSOTECHNIK engineers sheet metal joining systems for industry partners around the world. Sheet metal clinching is a cold-forming technique that joins two or more metal pieces without the use of fasteners, bolts, rivets or spot welding. Trusted by the manufacturing, automotive, appliance, housing, HVAC and furniture industries, R-SIMITCH sheet metal joining systems are an economical solution for your clinch joining system needs.

R-SIMITCH Sheet Metal Joining Systems

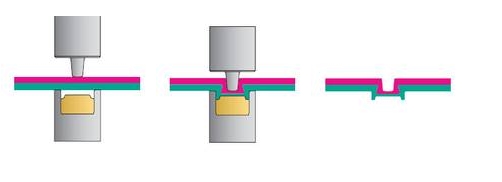

Process Sequence

A solid connection:The materials are strained plastically at the connecting joint and are therefore stronger. There are no stress concentration factors. The RSM joining system is also environmentally advantageous, especially when compared to welding. This is most evident in joining aluminum and coated or prepainted sheet metals.

Cutting costs with R-Simitch:

Besides the directly measurable cost advantages, considerable savings can also be made with a much simpler production sequence. For example, it is often possible to punch, bend and join in one progressive die. This saves an entire working cycle as well as transportation to the joining station – or welding shop. Which is a great advantage in terms of logistics.